Metal Works Systems

Our Facilities

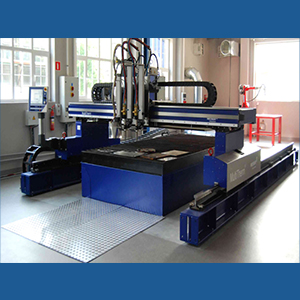

of reputed brand. CNC Plasma Cutting Machines at Jagteq delivers optimum

cutting with high quality and straight cutting edges. The machines have high

cutting speed and complete the job accurately and fast. Our CNC Plasma

Cutting machines are excellent automation solutions with multi-functionality.

They can cut to maximum thickness and are able to deliver high precision and

uniformity. Because they are operated with CNC Control, these machines are

minutely precise. The machines are highly cost effective and achieve highly

superior results. Being automated, they are safer than gas-cutting alternatives.

Shearing is a metal fabrication process used for trimming and removing unwanted material from sheet metal. It involves the use of a machine or tool, such as a bench shear, to slice through sheet metal with extreme precision. The Jagteq facility has state-of-the-art shearing tools that achieve flawless results. Our machines have the ability to make straight line cuts on flat sheet stock. They deliver straighter and smarter edge than traditional torch cutting. We are proud that our machines achieve no loss of material leading to minimum waste. Jagteq has the high-end shearing equipment needed to cut and process the metal.

a range of machining capacities. It is the one stop CNC machining in the

manufacturing processes. It has many benefits, such as reducing machine

replacement time and enhanced production efficiency. Our CNC Machine

Centre is able to perform various operations such as milling, drilling, boring,

tapping and lathe operations. The CNC Machine Centre at Jagteq completes

these operations with highest precision, high quality and excellent surface

finish. It also reduces production time and facilitates higher and smarter

productivity. It is one of the reasons why Jagteq is trusted by industry

stalwarts.

quality. At Jagteq, the inspection involves various points at processes and

tools. The production excellence depends a great deal on how closely a

material is inspected. We use high quality inspection material including

calipers, high gages, gage pins, angle or sine plates etc. The inspected factors

include material condition such as scratches, abrasions, surface finish

requirements, changes in metal thickness, reduction, spin forming etc. The

best inspection means the best end result, best output and highest customer

satisfaction. At Jagteq, we have achieved it perfectly.

Our Facilities

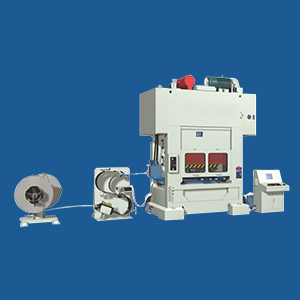

Jagteq has world class CNC Punching Machines of a reputed brand. These machines have achieved great degree of accuracy and precision. They are efficient performers and deliver uniform and accurate products in a timely manner. These CNC Punching Machines are intelligent automation solutions, which enable you to maximize your productivity in metal works. Our CNC Punching machines have a high level of processing flexibility. They are easy to operate and hassle free punching solutions. They can produce a wide range of metal parts of the highest quality standards. Thanks to their performance, our CNC Punching machines make the entire production process transparent, flexible and cost-effective.

The Jagteq metal works facility consists of excellent CNC Machines. These large format bending machines are fully automated, reliable bending solutions. Their best in class bending technology enables you to adapt them to your specific requirements and applications. These CNG Machines produce simple as well as complex parts with accuracy, precision and cost-efficiency. They are ideally suited for simple as well as complex bending applications in any format. With these CNC bending machines at hand, Jagteq is able to deliver the products of optimum quality and performance, in fair price and required timeline. Our well-equipped facility is our asset.

Our array of machinery signifies the versatility to perform a wide variety of manufacturing methods. Jagteq contains a robust and high performing Casting and Forging Machine in its state-of-the-art facility. The machines are dependable and well maintained. With the help of these world class Casting and Forging machines, Jagteq has a proven track record of creating high quality metal parts. Forging creates tough and strong products with uniform structure and composition. Casting gives a large range of alloy choices and does not have upper size limit. At Jagteq, our machines give you all the benefits of this best technology.

Our quality department ensures that, at every stage of all the processes, stringent quality control is maintained. Our quality policy is defined by our vision. Jagteq and its team is dedicated to meeting or exceeding its customers’ needs and expectations. We aim to become quality leaders in products and services. Performance, reliability, competence and customer satisfaction are our quality parameters. Our management and staff are committed to follow quality principles. We foster a culture of quality improvement and growth. We are committed to upgrade our customers’ skills, quality control our processes, maintain safety in our work and deliver the best in class.

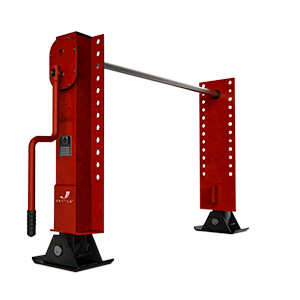

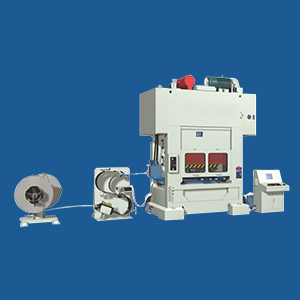

To be competitive in the global market we strive to get the best technology and invest in the latest machinery. Pressing requires high forces to be safely and accurately regulated. The Press Shop at Jagteq consists of all the essential technologies for presses, metal cutting, bending and roll-forming. Our Press Shop has both types of presses- mechanical presses and hydraulic presses. Jagteq facilitates pressing applications with a wide range of metal works. The latest technology ensures identical precision and accuracy. To operate this Press Shop, we have trained and expert manpower to execute the operations.

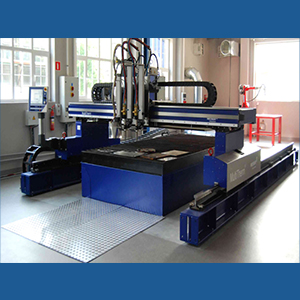

The Jagteq facility is equipped with user-friendly CNC Plasma Cutting Machines of reputed brand. CNC Plasma Cutting Machines at Jagteq delivers optimum cutting with high quality and straight cutting edges. The machines have high cutting speed and complete the job accurately and fast. Our CNC Plasma Cutting machines are excellent automation solutions with multi-functionality. They can cut to maximum thickness and are able to deliver high precision and uniformity. Because they are operated with CNC Control, these machines are minutely precise. The machines are highly cost effective and achieve highly superior results. Being automated, they are safer than gas-cutting alternatives.

Shearing is a metal fabrication process used for trimming and removing unwanted material from sheet metal. It involves the use of a machine or tool, such as a bench shear, to slice through sheet metal with extreme precision. The Jagteq facility has state-of-the-art shearing tools that achieve flawless results. Our machines have the ability to make straight line cuts on flat sheet stock. They deliver straighter and smarter edge than traditional torch cutting. We are proud that our machines achieve no loss of material leading to minimum waste. Jagteq has the high-end shearing equipment needed to cut and process the metal.

The CNC Machine Centre at Jagteq integrates the machine function and covers a range of machining capacities. It is the one stop CNC machining in the manufacturing processes. It has many benefits, such as reducing machine replacement time and enhanced production efficiency. Our CNC Machine Centre is able to perform various operations such as milling, drilling, boring, tapping and lathe operations. The CNC Machine Centre at Jagteq completes these operations with highest precision, high quality and excellent surface finish. It also reduces production time and facilitates higher and smarter productivity. It is one of the reasons why Jagteq is trusted by industry stalwarts.

Inspection is a part of the quality control system that can have great impact on quality. At Jagteq, the inspection involves various points at processes and tools. The production excellence depends a great deal on how closely a material is inspected. We use high quality inspection material including calipers, high gages, gage pins, angle or sine plates etc. The inspected factors include material condition such as scratches, abrasions, surface finish requirements, changes in metal thickness, reduction, spin forming etc. The best inspection means the best end result, best output and highest customer satisfaction. At Jagteq, we have achieved it perfectly.

Welding is used to create parts, structural components and equipment. It is an integral part of every industry. Welding is a technique used in automotive, construction and aerospace industries, to produce metal parts. At Jagteq, we are experts in different types of welding including MIG Welding, Stick Welding, TIG Welding and Orbital Welding. With a comprehensive study of your design plan, materials you want to use, your budget and required applications, we devise a customized welding solution for your project. Jagtecq has a balance of experience, expertise and excellence required to deliver the best results and highest quality in welding.

Having excellent metal finishing facilities is one of the strengths of Jagteq. In this process, the metal part might be deburred, painted, hardened, treated or assembled to make it ready for packaging or shipping. We leave no stone unturned to achieve precision in manufacturing. Our flexible and productive, in-house metal finishing facilities, make us a leader in metal work. We offer finishing options such as powder coating, lacquering, chrome plating, metal polishing, silk screen printing and so on. These options give you scope to choose what is best for your project, because it is very important to achieve the best finishes, colours and texture for your product.

Products